HIGH EFFICIENCY PUMPS

The best performance, even tailor-made

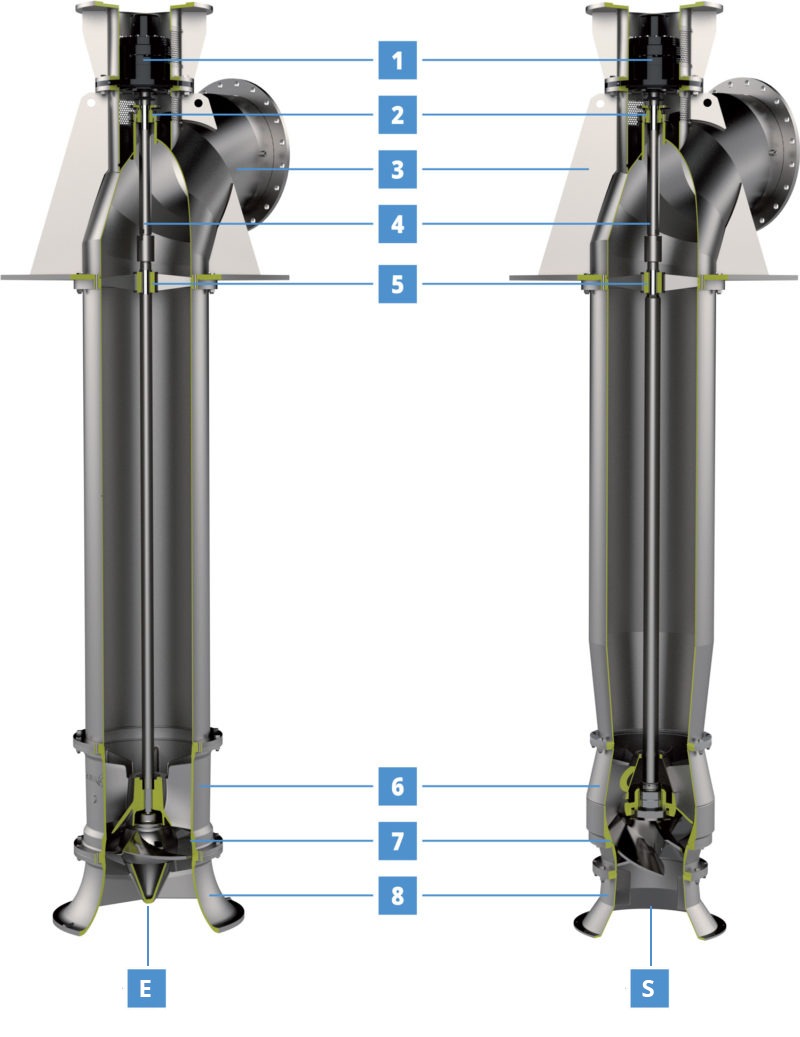

1 – SHAFT THRUST SUPPORT

With roller bearings, grease/oil lubricated, produced by the main manufacturers, with an average life of more than 50.000 hours of working.

2 – SHAFT SEAL

Generally packed stuffing box, reliable and of easy maintenance. The mechanical seal or other solutions are used when necessary.

3 – DELIVERY ELBOW

Sturdy electrowelded steel structure, composed of a flanged elbow with reinforced ribs and a supporting plate; seal seat and support housing.

4 – TRANSMISSION SHAFT

Made of high-resistance rectified steel, carefully sized for maximum torque and composed of dimensioned segments for the highest rigidity, joined by rigid sleeve couplings. At its thinnest points, the shaft is equipped with replaceable protection bushes.

5 – SHAFT GUIDE BEARINGS

Standard configuration includes special anti-abrasive rubber bearings lubricated by the pumped liquid; grease-lubricated bronze guide supports or oil lubricated ball bearings with protected transmission.

6 – PUMP BOWL

With vanes having an outline designed to allow the best conveyance of the fluid threads, to guarantee the maximum reduction of hydrodynamic losses and a better energy recovery.

7 – WEAR-RESISTANT RING

Replaceable ring mounted at the impeller housing, to protect the pump bowl, when necessary.

8 – BELLMOUTH

Made of a conical segment of pipe having a special outline specially designed to minimize losses at the inlet and limit the formation of vortex at the minimum submergence.

E – PROPELLER

Composed of a spherical hub and blades with hydraulic outline carefully designed for high efficiency, adjustable when the pump is stopped and disassembled in standard configuration; for larger diameters, the version with adjustable blades with pump in motion is also available, with a manual / electric control device.

S – MIXED FLOW PROPELLER

Open mixed flow propeller with blades’ hydraulic outline carefully designed to ensure high efficiency.

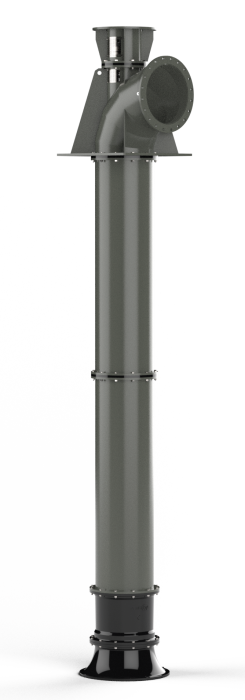

E

Propeller pump

| Drive | Electric motor / Motor clutch set / Tractor |

|---|---|

| Installation | Stationary |

| Pump type | Propeller |

| Transmission | Lubricated by the pumped liquid / grease / oil |

| Metallurgy for fresh water | Painting with zinc phosphate epoxy primer and polyurethane enamel / Hot galvanized |

| Metallurgy for sea water | Stainless steel / FBE coating (Fusion Bonded Epoxy) |

| Main features | High flow at low head, flow regulation by adjustable blades, high efficiency and reliability, remarkable versatility and adaptability. |

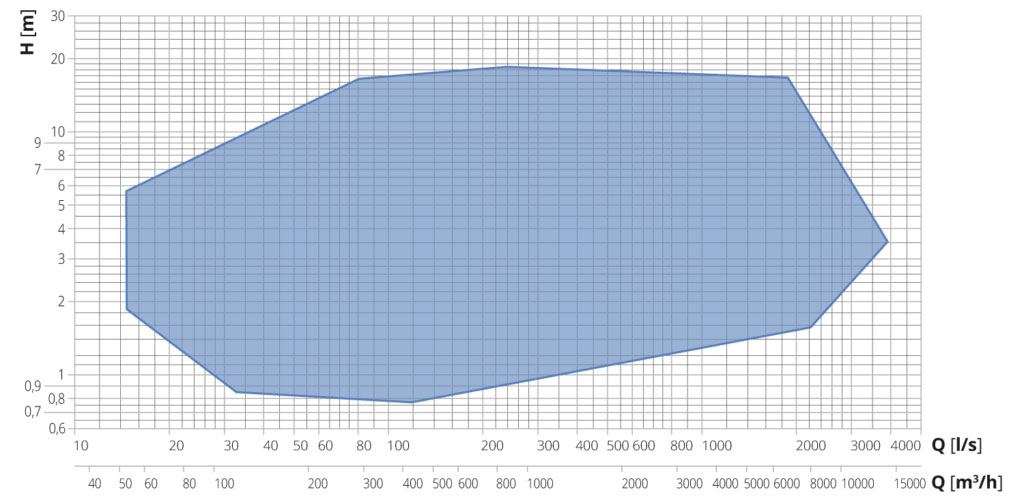

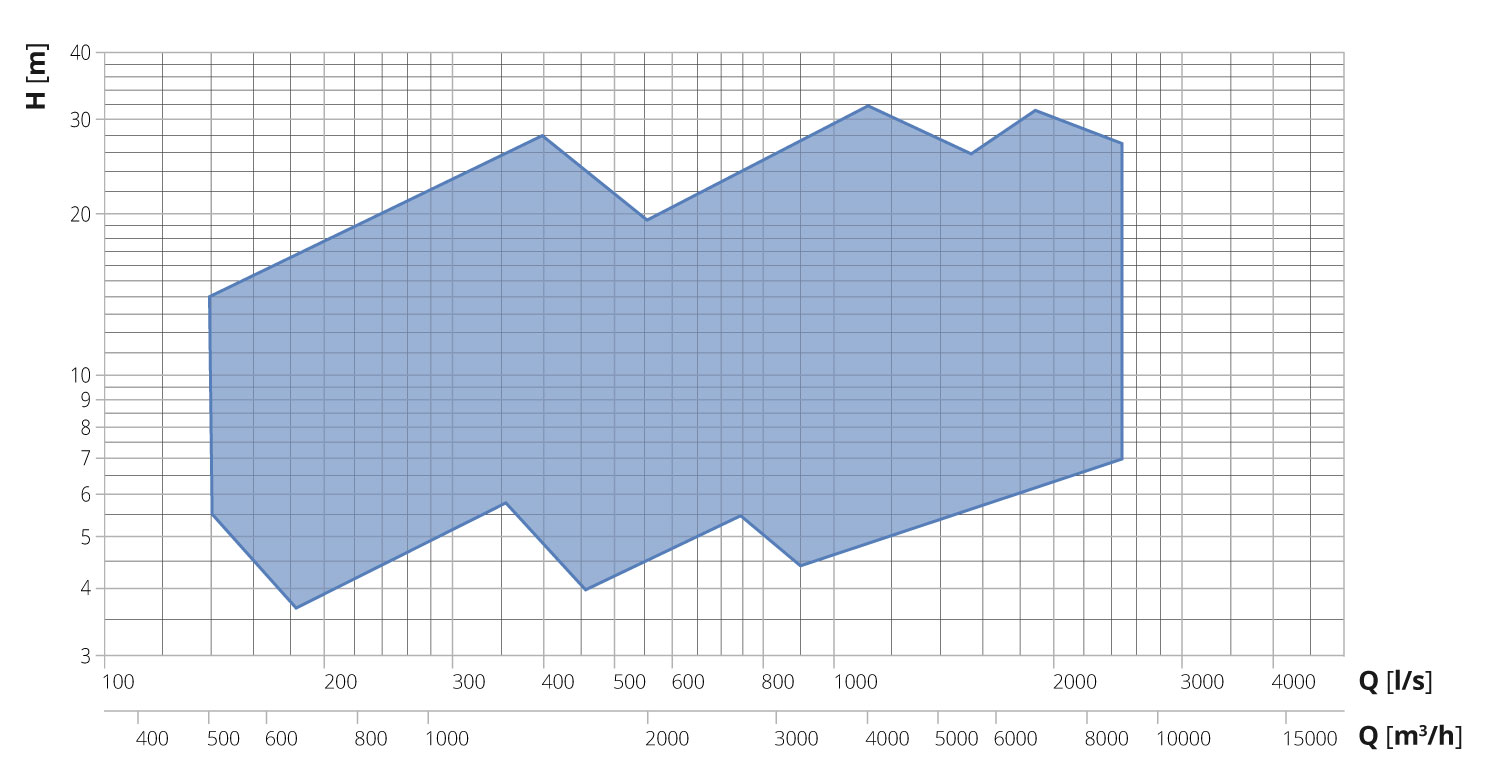

PERFORMANCE RANGE

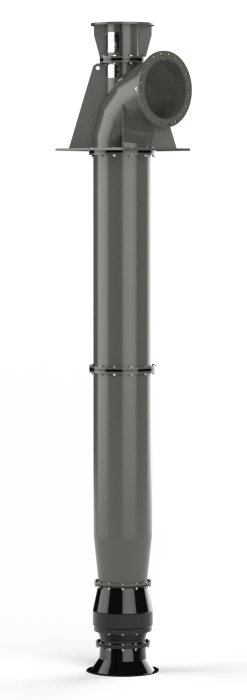

S

Mixed flow pump

| Drive | Electric motor / Motor clutch set / Tractor |

|---|---|

| Installation | Stationary |

| Pump type | Mixed flow |

| Transmission | Lubricated by the pumped liquid / grease / oil |

| Metallurgy for fresh water | Painting with zinc phosphate epoxy primer and polyurethane enamel / Hot galvanized |

| Metallurgy for sea water | Stainless steel / FBE coating (Fusion Bonded Epoxy) |

| Main features | High flow at medium head, hydraulic configuration optimized for high efficiency with anti-clogging open impeller, remarkable versatility and adaptability |

PERFORMANCE RANGE

INSTALLATIONS

EVN | SVN

Vertical installation with delivery elbow above the laying surface

Lifting plant for reclamation on the banks of the river Meduna, Peressine (Pordenone, Italy), n.2 EVN 60 pumps, total capacity of 2,600 l/s.

EVS | SVS

Vertical installation with delivery elbow under the laying surface

Lifting plant for reclamation on the banks of the river Brenta, Padua (Italy), n.3 SVS 75 pumps, total capacity of 4,800 l/s.

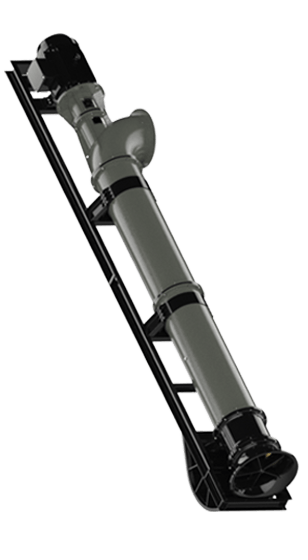

EBN | SBN

Oblique installation with frame

Lifting system for cotton irrigation on the Omo River, Ethiopia, n.4 SBN 60 pumps, total capacity of 4,000 l/s.

EKN | SKN

Horizontal / vertical installation in dry room

Industrial bottles washing plant, beverage sector, EKN 40 pumps for recirculation of water and soda solution, total capacity 1,800 l/s.